Understanding Diecasting: The Course of and Its Purposes

Understanding Diecasting: The Course of and Its Purposes

Blog Article

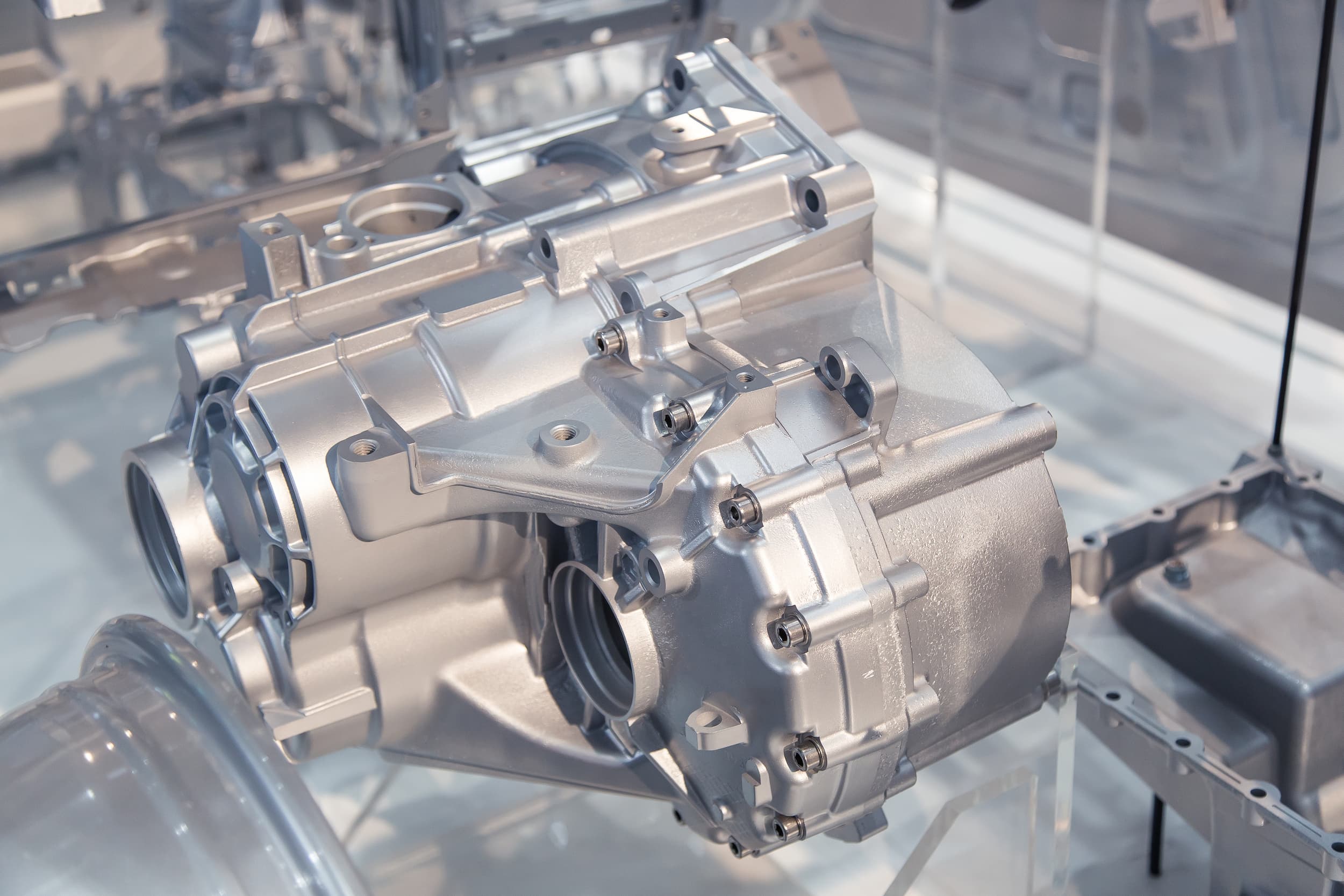

Diecasting is a pivotal process in modern manufacturing, playing an integral role in creating complicated metal parts that are produced with precision and efficacy. It involves pushing melting metal at high pressure into a mold cavity which results in components that have exceptional dimensional accuracy and high surfaces. In the midst of a rapid growth in industries, and as the need for top-quality parts rises, diecasting has continued to show its merits particularly in areas that need massive production of highly intricate components. This article will explore the diecasting process it's advantages, the benefits of diecasting, materials selections, and the wide range of use across different industries.

The diecasting process begins with the creation of a mold, known as a die, which is made of hardened steel that can withstand extreme pressure and temperatures. Once the mold is prepared metal alloys, such as magnesium, aluminum, zinc or copper are heated up until they melt. This molten metal is then injected into the die at high pressure, ensuring it fills all parts of the mold including intricate sections and walls that are thin. Pressure is maintained until the metal has solidified and at that point, the mold is opened, and the part that has been formed is ejected. This method of high-pressure ensures the product produced is precisely, with minimal need for additional machining or finishing.

One of the most significant advantages of casting dies is its ability to produce mass quantities. After the dies have been fabricated it is possible for the production of thousands of identical parts that are identical with little variation. This high level of repeatability is essential for industries that need large quantities of identical parts. Furthermore, diecasting is recognized for its material efficiency. It produces little debris, as any metal that is not used can be recycled and reused for subsequent casting cycles. This not only reduces cost of materials but also helps to promote green manufacturing methods by reducing the use of resources and reducing waste. The combination of high efficiency, high speed in material performance makes diecasting an appealing option that manufacturers are looking to enhance their manufacturing processes.

Diecasting has many benefits with regard to mechanical properties as well as performance. Parts made by diecasting are well-known as durable and strong that are crucial characteristics for components used in demanding applications. The fine-grain structure that forms in the process of rapid cooling the metal contributes to these properties that make diecast pieces suitable for use in environments with high stress. Moreover, diecasting allows for the use of thin walls and complex characteristics without jeopardizing the integrity of the finished product. This capability is particularly advantageous in the automotive and aerospace industries where the ability to reduce weight but maintaining strength in the structure is essential to improve fuel efficiency as well as overall performance. To obtain additional details please go to https://www.senadiecasting.com.my/

Diecasting's materials play a crucial role in determining the properties and efficiency of the final product. Aluminum is among the most frequently used metals because of its superior strength-to-weight ratio, corrosion resistance and excellent thermal and electrical conductivity. Zinc alloys are also well-known, offering high strength, ductility, and the capacity to make pieces with intricately detailed details. Magnesium alloys have the benefit that they are the tiniest structural metal. This makes them the ideal choice for any application where weight reduction is critical. Copper alloys are not as popular, are utilized due to their high electro-conductive properties and corrosion resistance. The choice of material depends upon the specifications of the project, which includes mechanical properties, physical conditions in the environment, and also cost issues.

Diecasting is an extremely efficacious and versatile manufacturing process that is integral to producing complicated metal parts that have the highest precision and uniformity. Its ability to create parts with intricate details precise tolerances, perfect tolerances, as well as polished surfaces makes it a valuable tool in a variety of fields, from automotive to aerospace to consumer electronics and beyond. Utilizing different types of material types further increases the flexibility of diecasting. It allows companies to select the ideal alloy to suit their requirements. As the technology evolves and the demand for high-quality, affordable components increases and increase, diecasting will continue to be an essential element within the production process which will drive innovation and superiority in production.